A very special class of materials can “remember” their shape. After deformation you can just heat them and they return to their original form. A number of different shape memory materials have been developed, but one in particular has become a standby in many applications.Nitinol’s unique properties of shape memory and superelasticity result from a phase transformation within its crystal structure that happens with temperature change. At lower temperatures the structure is martensite, a weaker form, and at higher temperatures, austenite, which is stronger. In addition, martensite can also occur at higher temperatures where the material is stressed. The mechanical properties of Nitinol actually change with stress, and with relatively small changes in temperature.

Shape memory

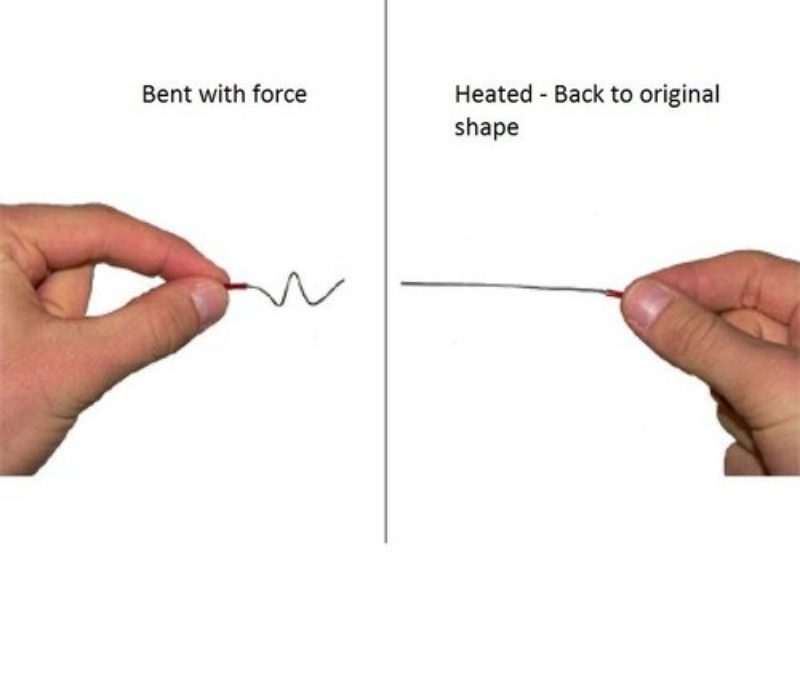

To demonstrate shape memory behavior you can deform a Nitinol item at a low temperature, really bending it out of shape. Then heat it and watch it return to its original shape, as if by magic. Nitinol in its martensitic (low temperature) state is easily bent or twisted into a new shape. Then, as it is heated it passes through a narrow range of temperatures where it changes to an austenitic structure and reverts to its previous shape.

The temperature above which the material remembers its high-temperature form is called the transformation temperature.

The useful range of the material is typically between 0 degrees and 100 degrees Celsius [32 F and 212 F], a very narrow range when you think of metals.The transformation temperature can be controlled by small changes in the alloy’s composition and how it is heat treated. The temperature to start or finish the transformation can be controlled within a degree or two, if needed.

To use the shape memory property once the part is fabricated, it needs to be shape set. Create a form and hold [the part] in that shape. Constrain it has to be under load. Then you heat treat it at 500 degrees Celsius and water quench or fast-cool it. Then, if the piece is later pulled, pushed or bent out of shape below its transformation temperature, when heated past its transformation temperature, it will return to its remembered shape.

Superelasticity

Above its transformation temperature, Nitinol displays superelastic behavior. This is due to martensite forming in areas that are stressed, even though the temperature is above where martensite normally occurs. Then, when the stress is removed this martensite returns to the undeformed austenitic state. This makes a Nitinol part very springy in feel and able to return to its original form even after huge deformation. Though Nitinol is known as a shape memory alloy, many of its applications make use of its superelasticity.

Where most metals can tolerate only a small fraction of a percent of strain without permanent deformation, above its transformation temperature Nitinol routinely can take up to an eight percent strain and afterward return to its original shape. Nitinol is also known for its fatigue strength.

Making parts

Laser cutting and EDM (electrical discharge machining) are usually the processes of choice with Nitinol. This metal can be conventionally machined, but it’s not easy to deal with.

The medical devices used to keep blood vessels open, called stents, and similar devices are often fabricated by laser cutting Nitinol tube. The process starts with a tube of very precise diameter, roundness and wall thickness. A laser cuts a complex pattern from one end of the stent to the other. Cutting might take five minutes for a 3 mm x 18 mm (0.12″ x 0.71″) stent, Or, depending on the size and complexity of the part, from 30 seconds to 45 minutes.

Surface fi nish is critical on Nitinol parts used for their superelasticity and fatigue strength. Any surface irregularities or micro cracks can cause fatigue failure. Processes such as electropolishing take care of this, and also can remove any heat-affected material from the part after laser cutting or EDM.

Nitinol is available in sheet, foil, tube, bar, wire and other forms.Please contact us,If you need to talk with our technical department,