Nitinol Composition

This nitinol alloy is composed of nickel and titanium. It contains these two elements at approximately equal atomic percentages. Nickel is a known allergen and it might also have carcinogen properties. Due to this reason the nickel content of this alloy has raised great concerns about its usefulness in the medical industry. Nitinol alloy has been widely used in aerospace, automobile, medical equipment and other fields due to its excellent properties.

Aerospace

Nitinol applications in aerospace mainly include pipe joints on aircraft, as well as spacecraft antennas, fasteners, connecting parts, electrical connections and electromechanical actuators.

Automobile industry

Nitinol is commonly used in the clutch of heat-resistant fan of automobile engine, automatic exhaust regulating nozzle, automatic switch of radiator hole of diesel engine and shape memory spring of oil filter of jet engine.

Medical instruments

Nitinol has been successfully used in dental orthodontics, surgical orthodontics and plastic surgery and cardiovascular minimally invasive interventional therapy. At present, surgical sutures, cerebral aneurysm clips, contraceptive rings, artificial hearts, artificial kidneys with miniature pumps and so on have been put on trial in medical clinics.

Civilian products

Civilian products mainly include super elastic glasses frame, mobile phone antenna, women’s corset bracket, high elastic and high toughness fishing wire, earphone headsets and so on.

Nitinol Production

Extremely tight compositional control is required for making this alloy. Due to this reason it is very difficult to prepare this alloy. The extraordinary reactivity of titanium is another obstacle in its preparation. Two primary melting methods are presently used for this purpose:

Vacuum Arc Remelting: In this method, an electrical arc is struck between a water cooled copper strike-plate and the raw materials. Water cooled copper mold is used for melting the constituents in high vacuum to prevent carbon introduction.

Vacuum Induction Melting: The raw materials are heated in a carbon crucible using alternating magnetic fields. This is also accomplished in high vacuum; however, carbon is introduced in this process.

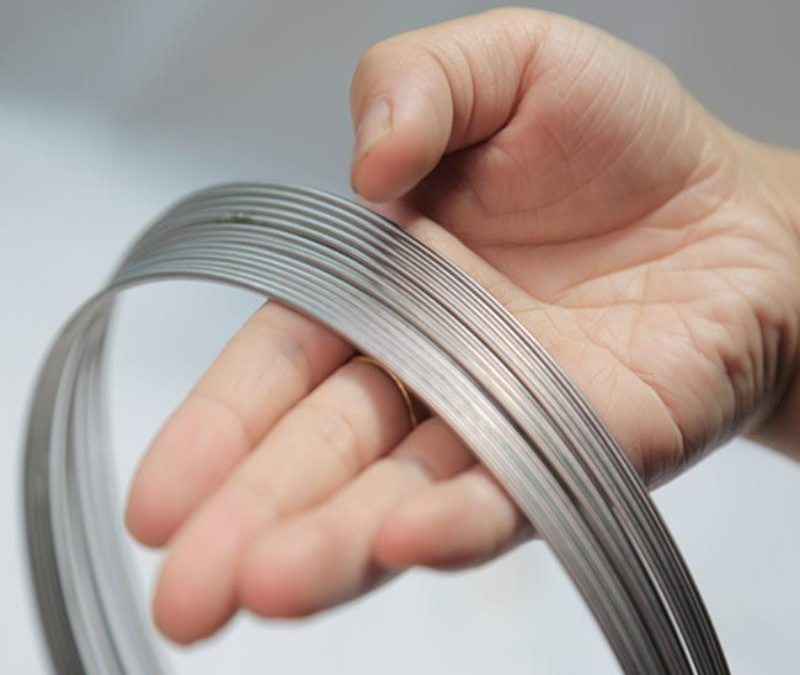

Nitinol Picture

There are no considerable amounts of data showing the product of one method to be better than the other. Both these methods have different advantages to offer. Other methods like induction skull melting, plasma arc melting, and e-beam melting are also used for this purpose on a boutique scale. Physical vapor deposition process is also used in laboratories.

Nitinol Availability

Nickel titanium is available in various forms including wires, tubes, sheets and springs.

Nitinol is counted among the most useful metal alloys with numerous industrial and medical applications.